Fisker’s Manufacturing Strategy Is the Largest Experiment In Making EVs Affordable

David Shultz reports on clean technology and electric vehicles, among other industries, for dot.LA. His writing has appeared in The Atlantic, Outside, Nautilus and many other publications.

I’ve spilled considerable ink on California-based electric vehicle companies like Rivian, Faraday Future, Vinfast, and Tesla. But one company that’s flown under the radar is Fisker. Backed by the charismatic auto industry legend bearing the same name, the company is planning to start delivering its first model, the Fisker Ocean, at the end of the month.

So what distinguishes Fisker from its myriad competitors? Their path to market. Specifically, Fisker has handed off the manufacturing of its upcoming EVs to partner companies Magna Steyr and Foxconn.

Shirking the responsibility of, you know, actually building your own car, comes with a host of pros and cons. Fisker’s eventual success or failure in the EV space may come down to how it balances and manages each.

From the highest level, outsourcing production lets Fisker do a couple of things. First, it allows them to get to market a bit quicker: building a factory can take years. Second, it reduces the risk and headaches that many other EV makers run into as they get manufacturing online. Magna Steyr, the manufacturer of the Ocean, is an established company with an excellent track record in the industry, assembling cars for brands like BMW, Mercedes, Jaguar. Previous reports have even revealed that the Ocean will be built on a modified version of a Magna Steyr electric vehicle platform.

The existing expertise has helped Fisker get to market quicker, and as more and more legacy automakers join the EV space, expedience may pay dividends. Avoiding the high upfront capital expenditure may have also helped the company keep their prices low. I’ve spent many paragraphs complaining about the high price of entry into the EV world. But at $37,499, the Ocean would be among the most affordable plug-in options on the market–especially in the SUV category. If the car is even close to competitive with offerings like the Ioniq 5 or the Kia EV6, that price should look very attractive to budget-conscious consumers.

The exact terms of the deal between Fisker and Magna Steyr aren’t public. But Daron Gifford, leader of Plante Moran’s Mobility Practice, says that assembly plus labor and overhead usually accounts for 15 to 20% of an automaker’s cost structure. But the price of relying on outside manufacturing is, of course, relinquishing control of how many cars you can make.

“As you scale up, you reach a point when there's more of a tendency to want to be in control of your own production,” says Stephanie Brinley, principal analyst at S&P Global Mobility. “What you risk–whether you're working with Magna or Foxconn or someone else–is that your ultimate capacity is going to depend on what they're doing.”

Gifford agrees that outsourcing manufacturing might make it difficult or cost prohibitive for Fisker to make changes to its manufacturing processes on the fly. He also points out that the process adds a lot of complexity and operational risk for the company.

“It’s going to be a management challenge,” Gifford says. “But the bigger problem on top of the management challenge is the supply chain.” Sourcing the parts from around the world, shipping everything to Magna Steyr’s plant in Graz, Austria, assembling vehicles, and then loading them onto boats to send back to the U.S. is likely both costly and slow for Fisker. “If they sourced everything in Europe, it’s a shorter supply chain, but I suspect they did not,” says Gifford.

Outsourcing to Austria also complicates the picture with regard to the Inflation Reduction Act. Biden’s new infrastructure legislation includes language that requires EVs be assembled in North America to be eligible for the full discount. As such, this would exclude the Ocean from qualifying. However, last month Magna announced its intent to set up a manufacturing plant on U.S. soil, meaning that future runs of the Ocean may be eligible for the full rebate.

This isn’t to say that Fisker couldn’t add its own manufacturing further down the line once the brand is more established. That option, according to Brinley, is certainly on the table. But as it currently stands the company is already under contract with Foxconn for its second model—the Pear. The vehicle marks theTaiwanese electronics company's first foray into automotive manufacturing. And the agreement is more difficult to assess since all that is known about the Pear is that it will be built in Foxconn’s Ohio factory.

If Fisker’s partnership with manufacturers sees considerable success, other brands may seek to emulate their model. But up to this point–at least in the EV world–no one’s yet decided to outsource production to a third party manufacturer, making Fisker’s example the largest-scale experiment of its kind. Which is why, Brinley says, we may not be able to evaluate the success of the strategy for years to come.

“It's not a sprint, it's a marathon,” she says. “I think that if you take a broader view, the winner isn't necessarily decided in the next three years. A brand could stumble at the beginning and still be just fine in a decade. But it's easier to start off with a success than with a stumble.”

- Fisker and Apple Manufacturer Foxconn to Build Electric Cars - dot.LA ›

- Los Angeles Electric Vehicle News - dot.LA ›

- Electric Vehicle Startup Vinfast Targets 2023 for Public Offering - dot ... ›

- LAPD Creates Task Force To Respond to TikTok Kia Theft - dot.LA ›

- Fisker Ocean Rollout Unbothered by Tesla Price Cuts - dot.LA ›

David Shultz reports on clean technology and electric vehicles, among other industries, for dot.LA. His writing has appeared in The Atlantic, Outside, Nautilus and many other publications.

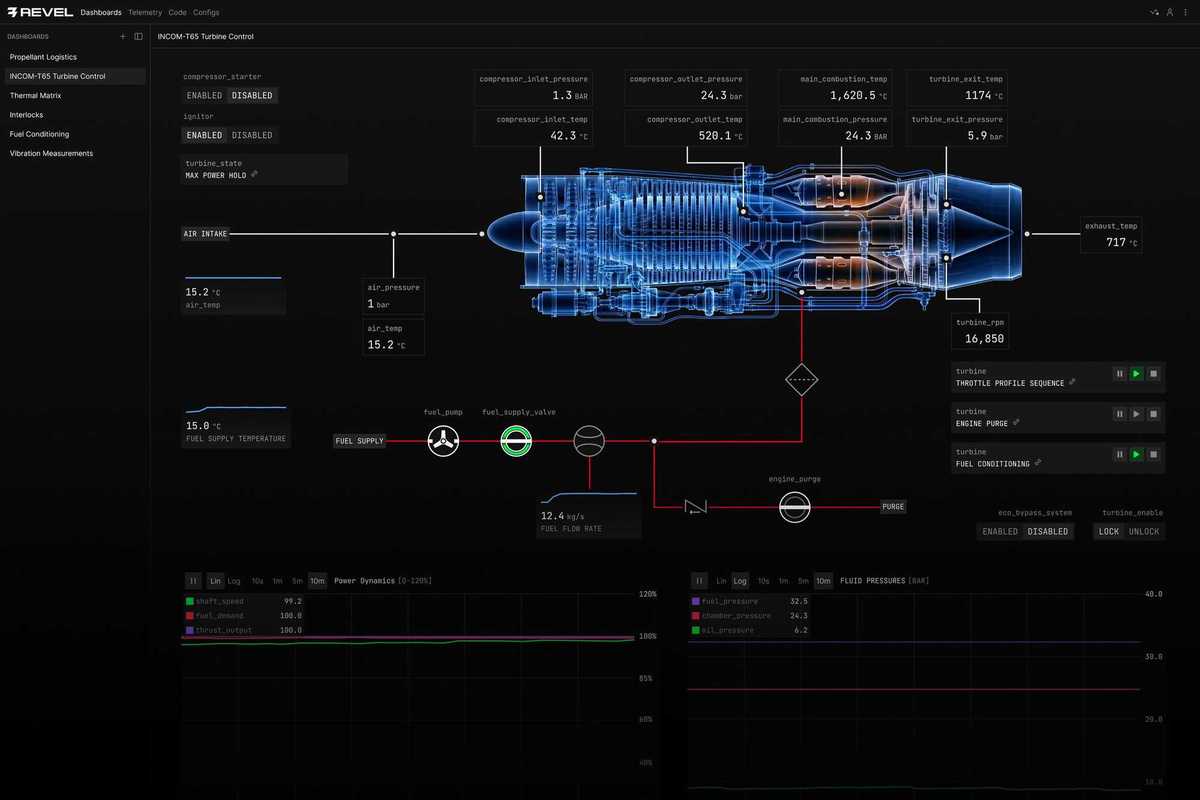

Image Source: Revel

Image Source: Revel