Aaron Hirschhorn, a well-known investor and entrepreneur in the Los Angeles tech scene who founded the pet sitting startup DogVacay died Sunday in a boating accident near Miami Beach, Fla. He was 42.

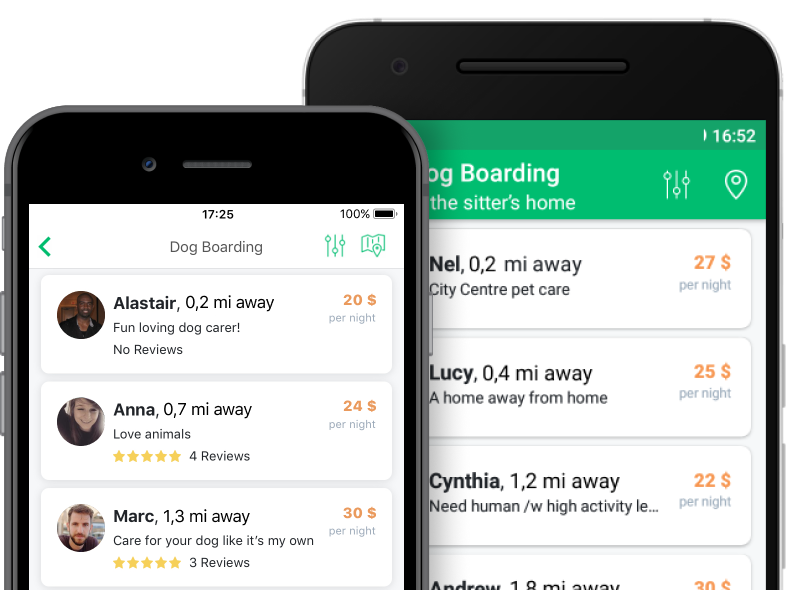

Hirschhorn started DogVacay with his wife Karine Nissim in 2012. The Santa Monica, Calif.-based company raised nearly $50 million and was a leading competitor in the pet services industry before being acquired by Rover in 2017.

Hirschhorn moved from Los Angeles to Miami Beach about three years ago, according to the Miami Herald.

Hirschhorn held a seat on Rover's board for a year. A month ago on LinkedIn, he called news of Rover's plans to go public via a SPAC deal "an amazing day."

"All of us at Rover were saddened to learn of Aaron's sudden passing. Our thoughts are with his family, friends, and colleagues during this painful time," Rover said in a statement provided to GeekWire on Wednesday. "His love of animals and commitment to pet parents was exemplified in his founding and leadership of DogVacay and Gallant, but his vision for what was possible in the pet industry went well beyond what he already had accomplished."

In 2018 Hirschhorn founded another pet-focused startup called Gallant, which stores dog stem cells so that they're accessible for future treatments.

The Miami Herald reported that the Florida Fish and Wildlife Conservation Commission and the U.S. Coast Guard reported a crash on Sunday between a 38-foot Chris-Craft motorboat and a personal watercraft.

Hirschhorn was reportedly riding his electric foil surfboard and died at the scene. In an Instagram post on Monday, his wife wrote: "My beloved husband of ten years died yesterday in an accident. We are broken and will never be the same."

Hirschhorn's Instagram shows numerous family images and scenes from his active lifestyle. "I play sports and get hurt a lot," his profile description reads.

The photo feed also illustrates his love for dogs.

After the Rover acquisition, Hirschhorn called the growing of DogVacay "an incredible journey."

"Our goal has always been to make quality pet care accessible to everyone, and with Rover and DogVacay's experience and expertise, we will continue to create the best solution for our host community, our pet parents and most importantly, our pets that we love as family," he said at the time.

According to the Gallant website, Hirschhorn founded that company "after experiencing the power of regenerative medicine for himself" when he underwent a single stem cell treatment "to heal a debilitating back injury."

Hirschhorn pitched Gallant in a 2019 episode of the ABC TV series "Shark Tank" and snagged an investment from Lori Greiner and Anne Wojcicki, co-founder and CEO of 23andMe.

The Miami Herald reported that Hirschhorn is survived by his wife and their three young children: a daughter in kindergarten, a son in first grade and a son in second grade.

DogVacay is a pet sitting app that was sold last year to Rover.

DogVacay is a pet sitting app that was sold last year to Rover.