A New Design Out of UCLA Aims to Revolutionize Batteries

David Shultz reports on clean technology and electric vehicles, among other industries, for dot.LA. His writing has appeared in The Atlantic, Outside, Nautilus and many other publications.

Faster charging, longer life, cooler temperatures.

For batteries, it’s usually a “choose one of the above” scenario.

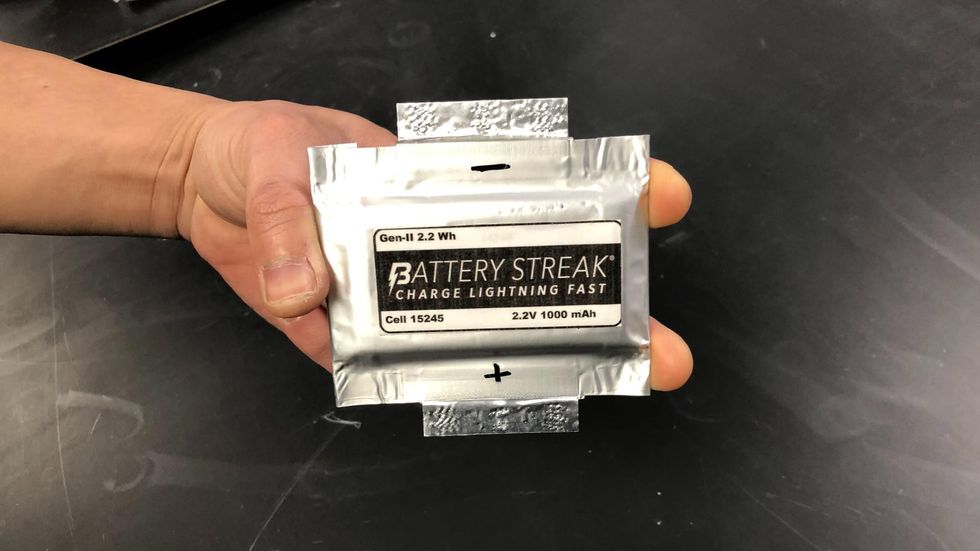

But Battery Streak, a fledgling startup based in an unassuming business park in Camarillo, CA, says it has all three, and they have it today.

“Our technology, in its current state, is something that we're bringing to market today,” says Dan Alpern, VP of Marketing at Battery Streak. “We're out of the lab and ready to go now.”

Given those claims, it’s not surprising that Battery Streak says they’ve attracted attention from major multinational brands, the U.S. military and electric vehicle manufacturers. Their batteries offer lightning-fast charging: Up to 80% capacity in 10 minutes. This alone would make the technology attractive for a variety of applications, but the company says it can hit those numbers while maintaining temperatures lower than that of the human body—all while maintaining a higher capacity across more cycles than traditional lithium-ion batteries are able to provide. Battery Streak’s test results show their product retains 80% of its capacity after 3,000 charge/discharge cycles. Today’s best lithium-ion batteries usually drop to 80% in about 1,000 cycles.

EV’S New Hope: Niobium

The secret sauce behind Battery Streak’s impressive stats is a rare metal called niobium. Element number 41 on the periodic table, niobium naturally reacts with oxygen to form a porous crystalline structure known as niobium oxide or niobia. The molecule’s shape gives it an incredible amount of surface area—which is what makes it so useful in battery design.

When charging a traditional battery, positively charged lithium ions start at the lithium metal cathode and migrate to a negatively charged anode. The anode is usually made of graphite—a crystalline carbon structure that traps and holds the ions in a process known as intercalation. This works well enough, but it requires the lithium ions to penetrate deep into the graphite lattice and undergo a chemical phase transition, releasing heat. The process can also get bogged down if the metal ions don’t penetrate deep enough into the carbon matrix and instead clump to form a metal coating. This is lithium plating, and it’s a massive problem facing batteries of the future and today.

Replacing the graphite in the anode with niobium solves—or at least improves—both of these problems. Due to the larger surface area of the niobium oxide molecules, lithium ions don’t need to penetrate deep into the crystal lattice or undergo any phase transitions to remain in place. Instead, the lithium ions nestle onto the surface of the niobium lattice. Easy on, easy off, so to speak.

Most of the world’s naturally occurring niobium can be found in Canada and Brazil and the mines and supply chains are robust thanks to the metal’s long history as a component of steel alloys. CBMM, a Brazilian niobium mining company has invested $5 million in Battery Streak and supplies all of the niobium for their batteries. Additional funding has come from a National Science Foundation grant and a pre-seed round from Act One Ventures, bringing the total to $6.5 million.

The battery design was first conceived at UCLA by a team of researchers including Bruce Dunn and Sarah Tolbert.

“These professors came to the licensing group and basically said, ‘Hey, we got this great new technology, find somebody to spin it out,’” says Battery Streak President David Grant.

Grant, who has previously founded several successful startups, is UCLA’s entrepreneur in residence.

“They looked around and said ‘Well, David's not doing anything, let's call him’,” he jokes. The company brought in Chun-Han “Matt” Lai from UCLA as technology development manager and started working on the commercialization process. Five years later, the company is ready to hit the market.

Creating Demand for a New Battery Type

Battery Streak’s ultimate goal isn’t to become a battery manufacturing giant…at least not yet. Their current business model is to make and supply the niobium nanostructures to battery manufacturers or to license the production technique to larger companies. In order to get these contacts, they have to convince the original equipment manufacturers (OEMs) selling the downstream products to give this new battery formulation a chance. A battery giant like Samsung isn’t going to switch up its battery chemistry unless there’s demand for the new tech. So, part of Battery Streak’s current strategy is getting their batteries into the hands of OEMs.They are targeting power tools, warehouse robots, drones, medical devices to start—all sectors where battery performance is critical and where there’s access to fast charging infrastructure.

When I toured Battery Streak’s manufacturing and design facility in June, the company was in something of a holding pattern. A standard COVID supply chain hiccup had them waiting on delivery of a 100-liter reactor that would let them move from producing a few grams of niobium per day to several kilograms. The reactor arrived a few days ago and as of July 19th, the company was drying its third large scale batch of product and sending out sample batteries for equipment manufacturers to demo.

Fortunately for Battery Streak, Dan Alpern says that battery manufacturers can build niobium batteries using all the existing lithium-ion equipment. There’s no need to purchase new machinery, parts, or packaging.

As impressive as some of Battery Streaks' numbers seem, there are two important caveats. The first is that to realize all their fast-charging potential, you need fast chargers. No standard home outlet can deliver enough power to let you charge your EV to 80% in 10 minutes.

Charging and discharging speeds are described on a C scale, where 1C means the battery charges or discharges in 1 hour. 2C indicates that the battery charges and discharges in 30 minutes, 3C indicates 20 minutes, etc, etc. Battery Streak’s tech allows them to charge and discharge in the 6C range. That’s incredibly fast. To deliver that much power to the battery, you need more voltage (or current) than a standard wall outlet (120 volts in the United States) can supply. That’s why the company is focusing its initial efforts on applications with easy access to higher voltage/current power supplies: auto shops, hospitals, warehouses, etc. Still, consumer electronics aren’t completely off the table: With a new type of charger, Grant says that his company’s batteries could offer improved charging times for phones or laptops, even with the current electrical grid.

A Fast-Charging Revolution?

As EVs become more mainstream, access to faster charging infrastructure will likely become more widespread. Many EV owners and landlords are installing level 2 charging (240 volts) in their houses or properties. Battery Streak is hoping to ride this wave into the future, but the electrical infrastructure required to reap the full potential of their technology isn’t that widespread yet.

Battery Streak is taking a more conservative approach in the electric vehicle sector. They’re in conversation with multiple automotive clients, but the second caveat facing their tech is that the niobium formulation reduces the total capacity of the battery by about 20% compared to a lithium-ion battery of the same size. The tradeoff is faster charging for reduced range. Some deficit can be offset by the reduced need for cooling gear, which also costs weight and space, but with so much consumer concern over range, other next generation battery technologies–especially solid state–may ultimately win the race. Scooters, bikes, and other micro-mobility use cases are also definitely on the table.

In terms of clientele, Battery Streak can’t say much because they’re bound by NDA’s with “pretty much everyone,” according to Grant. Their only large public contract is with the U.S. Navy. Their low temperature and high discharge rate has made Battery Streak’s batteries an enticing target for drone use. Quadcopter-style drones require considerable energy for takeoff, but use much less to maintain flight. The military was searching for a battery that could meet that dynamic power profile and recharge quickly in arctic environments, says Alpern, who served in the Navy on active duty from 1984-1990, and worked as a civilian employee from 2009-2021.

New Subsidies, New Opportunities

Battery Streak’s next phase is unclear. With its giant new reactor finally online, the company hangs on a precipice: If the test cells it’s sending out are well received by OEMs and the company can convince larger battery manufacturers to add a niobium formulation to their offerings, Batter Streak could potentially become worth billions, if only as a supplier of niobium powder.

There’s also the possibility that Battery Streak becomes a manufacturer. This wasn’t really at the forefront of the company’s plans even a few months ago, but according to Alpern, the winds are changing. There’s a possibility of setting up a factory in Kentucky using $50 million of state and federal funds allocated for clean energy initiatives to help replace coal jobs in the region. There are also whispers about Department of Energy subsidies.

“We're looking at Nevada, we're looking at Texas, we're looking at Arizona, we’ve spoken with North Carolina,” says Alpern.

Such an investment wouldn’t be unheard of for a niobium battery startup either. Earlier this month, UK-based Nyobolt secured $59 million in Series B funding to begin construction on a manufacturing facility that could come online as early as 2023. Another UK-based competitor, Echion Technologies, has also been in the news.

With the space clearly heating up, the race to market is on. Battery Streak says it’s hoping to have its first production batteries commercially available within the year.

- Tesla's Shift to Lithium-Iron Batteries Could Signal a Shift - dot.LA ›

- Electric Vehicles' Rise Could End SoCal Car Dealerships - dot.LA ›

- Lithium-Ion Batteries Might Have a Fire Problem - dot.LA ›

- How Battery Streak Plans to Charge Batteries Within Minutes - dot.LA ›

- How Haven Energy is Making Battery Installation Easier - dot.LA ›

David Shultz reports on clean technology and electric vehicles, among other industries, for dot.LA. His writing has appeared in The Atlantic, Outside, Nautilus and many other publications.

Image Source: Tinder

Image Source: Tinder Image Source: Apple

Image Source: Apple