Hexagon Purus Places Multiple Bets on Electrified Trucking

David Shultz reports on clean technology and electric vehicles, among other industries, for dot.LA. His writing has appeared in The Atlantic, Outside, Nautilus and many other publications.

When experts talk about the future of the energy economy, technologies are often described as winners or losers.

“Solar will beat nuclear.”

“Lithium iron phosphate will dominate lithium nickel manganese cobalt.”

“Geothermal is a better bet than tidal.”

Nowhere is this contest more pronounced than in the long-range trucking industry where hydrogen is battling for supremacy against battery electric.

But according to Hexagon Purus there’s room for everyone at the party, at least for now.

The Californian branch of Norwegian parent company Hexagon Composites has recently set up an American branch in Ontario, California, which is independently listed and focusing on zero emission solutions to trucking. It’s early days still, but on a tour of the facility last week I was able to chat with executives about how the future might unfold and how the company’s strategy illuminates both the opportunity and uncertainty surrounding the transition.

The debate around the best way to decarbonize long range trucking has been ongoing for several years now, and two technologies have emerged as the front runners. Earlier this year, I outlined this technological arms race in our newsletter, but a quick recap never hurts.

In one corner there’s the electric truck, which stores energy in a battery and uses that to drive an electric motor.

In the other corner there’s the fuel cell electric vehicle (FCEV), which carries hydrogen onboard and uses a fuel cell to turn the gas into electricity that drives an electric motor.

Fuel cell electric vehicles offer more energy per volume and per weight than today’s best batteries. And because of that, they offer longer ranges, which is a huge deal for long range trucking. Hydrogen tanks can also be quickly refilled or swapped, meaning drivers don’t have to wait for batteries to recharge.

But hydrogen also faces major headwinds. There are currently only 54 hydrogen refueling stations in the United States, and every single one is in California. By contrast, electricity is ubiquitous. The grid–while far from perfect and definitely not ready to support a nation of predominantly EVs–is already installed, and there are nearly 50,000 EV chargers spread across the country. There’s also nowhere near enough green hydrogen to power the nation’s fleet of trucks. But where some might see an obstacle, Hexagon sees opportunity.

Engineers check rev an engine at Hexagon Purus' location in Ontario, California.

Photo by David Shultz

Hexagon Composites, the parent company, got its start making hydrogen storage tanks.

These tanks are similar to the propane tank you use to power a grill or a heater. But hydrogen is a much trickier molecule to store than natural gas or propane: It’s lighter and escapes through smaller holes, meaning the tanks need to be made to a higher standard. It’s also corrosive to metal, meaning Hexagon’s tanks are lined with an inert plastic. FCEVs, if they catch on, represent an enormous opportunity to expand that business.

In addition to the tanks themselves, the company makes racks to transport tanks, and instruments to inspect and certify said tanks. If hydrogen is going to catch on, the United States will need a way to ship the gas all over the country. Hexagon believes their cylinders, transport and storage technologies are perfectly positioned to take on that challenge.

That’s where Purus comes in. Major truck makers like Volvo, Daimler and Freightliner have at least some of their chips invested in fuel cell technologies. Hexagon Purus is working with these industry giants to integrate their hydrogen tanks into the fuel cells on these trucks. If the tech catches on, the trucking giants will probably take over the integration themselves, but Hexagon Purus CEO Morten Holum says that smaller fleets–street sweepers, boom trucks, construction, drayage, etc–will still need the service…and the tanks. Right now, the technology is firmly in the prototyping stage, and Holum estimates that a shift is probably still three to five years out. Hexagon has just 20 FCEV trucks on the road. But each truck boasts up to 800 miles of range—certainly long enough to completely disrupt the diesel truck industry.

Initially, when I toured the Hexagon Purus facility, I couldn’t help but wonder if all the hydrogen technology in development was on track to become obsolete the moment somebody develops a battery that can carry a fully loaded tractor trailer 600 miles. Truckers are only allowed to drive for 8 hours per shift, so even if they averaged a whopping 70 miles per hour, that means a driver can only cover 560 miles in a shift. Tesla’s range figures should always be taken with a grain of salt, but their upcoming Semi platform will reportedly come with either 300 or 500 miles of range (on level ground). The Semi platform is currently in the process of receiving EPA certification, suggesting that deliveries might begin soon. While 500 miles might not translate to quite enough real-world range to entice the longest of long haul truckers, signs seems to suggest the day is coming.

But in the back corner of Hexagon’s garage, I found the answer. They’re also working on a battery platform. The company is building 220 kWh battery packs with cells sourced from “household name” brands and integrating them into the trucks–up to three at a time. For an operation that, at present, makes its money selling hydrogen cylinders and accessories, it’s quite a hedge. But Holum says the company–at least the Purus arm–is actually quite “tech agnostic.”

“Of course, if you had a battery that was 20% of the weight of today's batteries that you could charge in 15 minutes, then hydrogen would not be a long term truck fuel,” Holum says. But that technology isn’t here yet, and decarbonizing trucking is a task that has to start today. “The problem that we have now is not one solution out-competing the other solution,” he says. “It’s that both solutions are really needed, and there isn’t enough [supply].”

Holum thinks that over the next 10 years there will be room and demand for both technologies in the trucking sector, with battery electric vehicles taking up jobs with shorter duty cycles–things like drayage and last mile delivery–while FCEVs handle the long range jobs with the heaviest loads.

Beyond that, batteries may improve to the point where they win the market, but Holum also points out that FCEVs still use batteries and so they also benefit from improvements in the tech. Hydrogen itself can also get better. Hexagon is experimenting with storing the molecule as a liquid instead of a gas. While this requires even higher pressures, it would allow dramatically more energy to be packed into the same volume.

After ten years, it’s anyone’s guess how the technologies will evolve, says Holum, but with irons in so many different fires, Hexagon is trying to position itself for whatever the future may hold.

David Shultz reports on clean technology and electric vehicles, among other industries, for dot.LA. His writing has appeared in The Atlantic, Outside, Nautilus and many other publications.

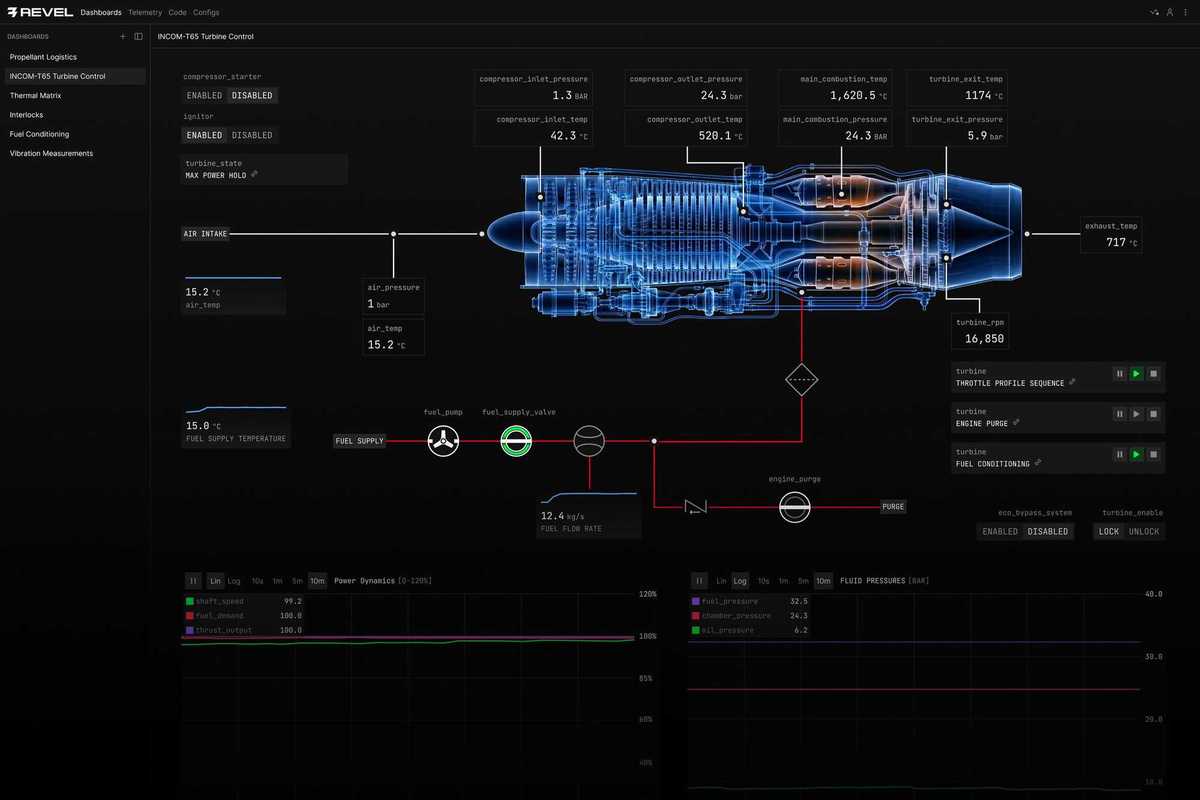

Image Source: Revel

Image Source: Revel